Shenzhen Dehong Vision Technology Co., Ltd.

Phone: 137 2892 0823

Fax: 0755-2372-6873

Email: 908450505@qq.com

Website: www.dhkj123.com

en.dhkj123.com

Address: Goldman Sachs Building, No. 18 Shajing

Center Road, Baoan District, Shenzhen

With the expansion of enterprise scale and output, the use of machine vision systems to replace people to complete production quality inspection has great application advantages. In response to this application requirement of the enterprise, Promex has launched a series of solutions for applying visual inspection technology to different industries.

Electronics manufacturing industry applications

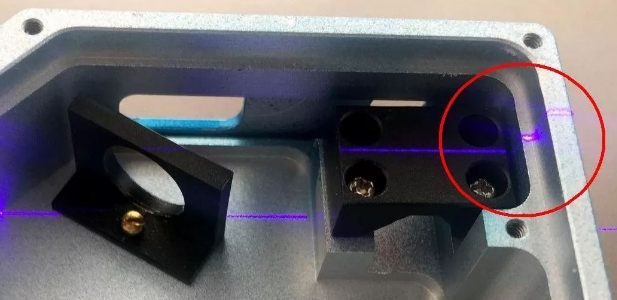

In recent years, due to the miniaturization of electronic assembly, the product production process is more demanding, but the output has continued to increase. As a result, relying on human eyes for inspection operations in the circuit board assembly and electronic product assembly process can no longer guarantee the quality and efficiency of production lines Vision technology is replacing people with fully automatic product inspection and process verification. For example, assembly gap detection can be implemented with laser contour sensors.

Laser profile sensor application --- measurement of part assembly gap

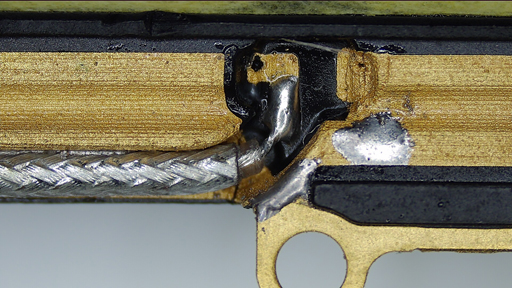

The advantages of visual inspection technology over artificial visual inspection are obvious. Compared with the human eye, machine vision inspection not only does not fatigue, and has the consistency and repeatability that humans do not have. The high-definition video microscope of Primex can enlarge the surface details of the product through a high-precision camera, and take pictures and analyze at a subtle level Can detect quality problems that cannot be found by the human eye, such as PCB board defects, mobile phone component defects, liquid crystal defects, wafer defects, optical lens defects, etc.

Video microscope application --- solder joint inspection

Automotive manufacturing industry applications

With the continuous improvement of the automation level of the automotive industry, some traditional detection methods can no longer meet the needs of high-beat and flexible production. The machine vision online detection technology with real-time monitoring functions has gradually been applied to mainstream manufacturers and has achieved good results. effect.

In an automated car production line, the vision system needs to be matched with a robot application when necessary, and established a connection with the PLC control system of the production line to achieve the functions of measurement, detection, positioning and identification. The visual inspection system has the following characteristics: non-contact inspection method is adopted, which improves the response speed and has a small impact on the production line; it has the performance of long-term stable and reliable repetitive work, suitable for automotive continuous line operations; suitable for safety risks High, poor ergonomics and poor environment work, and the accuracy rate has been greatly improved, which has improved the company's product qualification rate.

Precision instrument industry application

Machine vision has attracted wide attention from enterprises for its advantages of high detection accuracy and speed and the effective avoidance of subjectivity and individual differences brought about by manual detection. In the precision manufacturing industry, it has been used to detect the surface scratches and depressions of precision-machined parts, which is an ideal choice to achieve high-quality product production and reduce costs.

The quality requirements of precision parts on the surface of the parts are higher than ordinary parts, and the smoother parts can improve the wear resistance and corrosion resistance of the precision instruments and the ability to resist fatigue. For the detection of precision parts, it was previously measured with a two-dimensional image measuring instrument. With the improvement of accuracy requirements and measurement speed, Promeiss introduced the AI intelligent one-button measuring instrument. It implements auto-focus and auto-lighting technology, realizing real intelligent measurement, avoiding human error, personal measurement error, one-button measurement and analysis of data.

AI smart one-button measuring instrument

Compared with manual quality inspection, machine vision inspection can more accurately control product quality and reduce production costs. At the same time, it can work 24 hours a day, even in various harsh production environments that are not suitable for human work , The detection accuracy can be higher than manual detection.

attention

Shenzhen Dehong Vision Technology Co., Ltd.

Phone: 137 2892 0823

Fax: 0755-2372-6873

Email: 908450505@qq.com

Website: en.dhkj123.com

Address: 19th Floor, Goldman Sachs Building,

No. 18 Shajing Center Road, Baoan District, Shenzhen