Shenzhen Dehong Vision Technology Co., Ltd.

Phone: 137 2892 0823

Fax: 0755-2372-6873

Email: 908450505@qq.com

Website: www.dhkj123.com

en.dhkj123.com

Address: Goldman Sachs Building, No. 18 Shajing

Center Road, Baoan District, Shenzhen

In machine vision applications, camera calibration technology requires accurate camera internal parameters and external parameters as the input and prerequisites of the reconstruction algorithm. The most popular camera calibration algorithm is currently proposed by Tsai in 1987 [Tsai1987]. A three-dimensional calibration object with a non-coplanar dedicated calibration mark provides the correspondence between image points and their corresponding three-dimensional space points and calculates calibration parameters.

Through the calibration algorithm, the projection matrix of the camera can be calculated and the 3D measurement information of the scene can be provided. Without the absolute translation, rotation, and scaling parameters of the real scene, it is possible to achieve a similar transformation level of measure reconstruction. In order to meet the industry's high-precision vision calibration applications, a series of machine vision calibration board products have been introduced. Machine vision software can easily obtain camera calibration result data. It is a special high-precision calibration tool developed for universities, research units and machine vision integrators.

Calibration plate material: The materials are all soda glass: Russia uses a calibration plate with a silver color; Germany, Austria and other neighboring countries have a blue calibration plate; the United States and Japan have a yellow calibration plate. This color is determined by the coating process, and the quality of the calibration plate cannot be judged by the color alone. The high-end color of domestic calibration boards is yellow, and the cost of other colors is relatively low. Standard manufacturing process: The glass substrate is polished, cleaned, and coated. The film is firm and has fewer defects during post-production.

If one of the processes is reduced or the machine used is not very good, the product will be much cheaper and the quality will not be very good. Example: If it is produced according to the normal process, the size is 63mm * 63mm, and the price for mass production is at least one hundred yuan or more.

Material 2: The ceramic-based standard board has the characteristics of small thermal expansion coefficient, high strength, high hardness, good abrasion resistance, low thermal conductivity, and good resistance to acid and alkali. Its good surface diffuse reflection treatment solves the problem In the case of front light source, the problem of reflection of the glass material calibration plate can better identify the details of the calibration plate pattern to achieve higher calibration accuracy and measurement accuracy.

Material 3: Quartz material, the material has good light transmission, the biggest advantage: the coefficient of expansion is small. During the calibration of the instrument, it is less affected by ambient temperature. The corresponding cost is also high. Quartz materials are divided into JGS1 and JGS2. JGS1 is expensive. JGS2 is relatively cheap with bubbles inside. When selecting a calibration board, you must consider its use environment and accuracy, and choose a suitable calibration board. Visible flaws in accuracy and magnification can lead to dozens of times differences in volume prices.

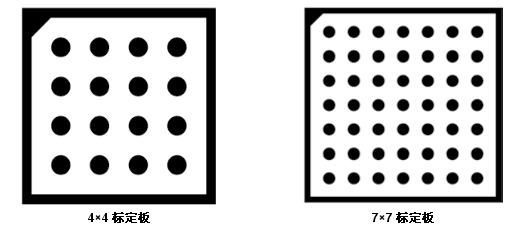

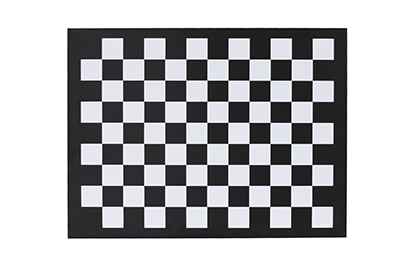

There are two types of calibration boards:

1) Solid circle array pattern

2) Chess board pattern

attention

Shenzhen Dehong Vision Technology Co., Ltd.

Phone: 137 2892 0823

Fax: 0755-2372-6873

Email: 908450505@qq.com

Website: en.dhkj123.com

Address: 19th Floor, Goldman Sachs Building,

No. 18 Shajing Center Road, Baoan District, Shenzhen